| Expert

A seasoned content specialist with over a decade of experience in corporate management and quality methodologies. Focused on translating complex TQM frameworks into actionable business strategies for global excellence. |

In the modern competitive landscape, success is no longer defined merely by profitability, but by the consistent delivery of exceptional value. For organizations aiming for longevity and market leadership, temporary fixes are insufficient; a foundational commitment to quality is essential. This is where Total Quality Management (TQM) emerges,not as a fleeting trend, but as a strategic philosophy that permeates every aspect of a business. TQM is a systematic approach focused on continuous improvement of products, services, and internal processes, driven by the ultimate goal of customer satisfaction. Unlike traditional quality control, which focuses on identifying defects after the fact, TQM is a holistic, preventive system involving every employee, from the CEO to the frontline staff. This framework provides the essential blueprint for business excellence and serves as the bedrock for achieving truly sustainable growth in any industry worldwide.

What Exactly is Total Quality Management (TQM)?

For decades, the concept of “quality” in business was often confined to the final inspection stage a gatekeeper role meant to catch defective products before they reached the consumer. This retrospective approach, known as quality control, was inherently reactive and costly, relying on fixing errors rather than preventing them. Total Quality Management (TQM) shattered this paradigm, introducing a comprehensive, forward-thinking philosophy.

Defining TQM: More Than Just Quality Control

TQM is a management philosophy that mandates long-term success through customer satisfaction. It achieves this by focusing on continuous improvement in all organizational processes, products, and services. The term “Total” is critical here: it signifies that quality responsibility is distributed across every department and every employee, not just a dedicated quality control team.

Essentially, TQM is defined by three core pillars:

- Customer Focus: Quality is ultimately defined by the customer’s perception and needs.

- Process Centricity: Errors are usually systemic, meaning TQM targets improving the underlying processes rather than just blaming individuals.

- Holistic Involvement: Everyone in the organization from executive leadership to support staff,must be committed and actively involved in quality initiatives.

TQM is not a set of tools; it is a fundamental shift in corporate culture and management mindset, ensuring quality is designed into the product and service delivery, not merely inspected out of it.

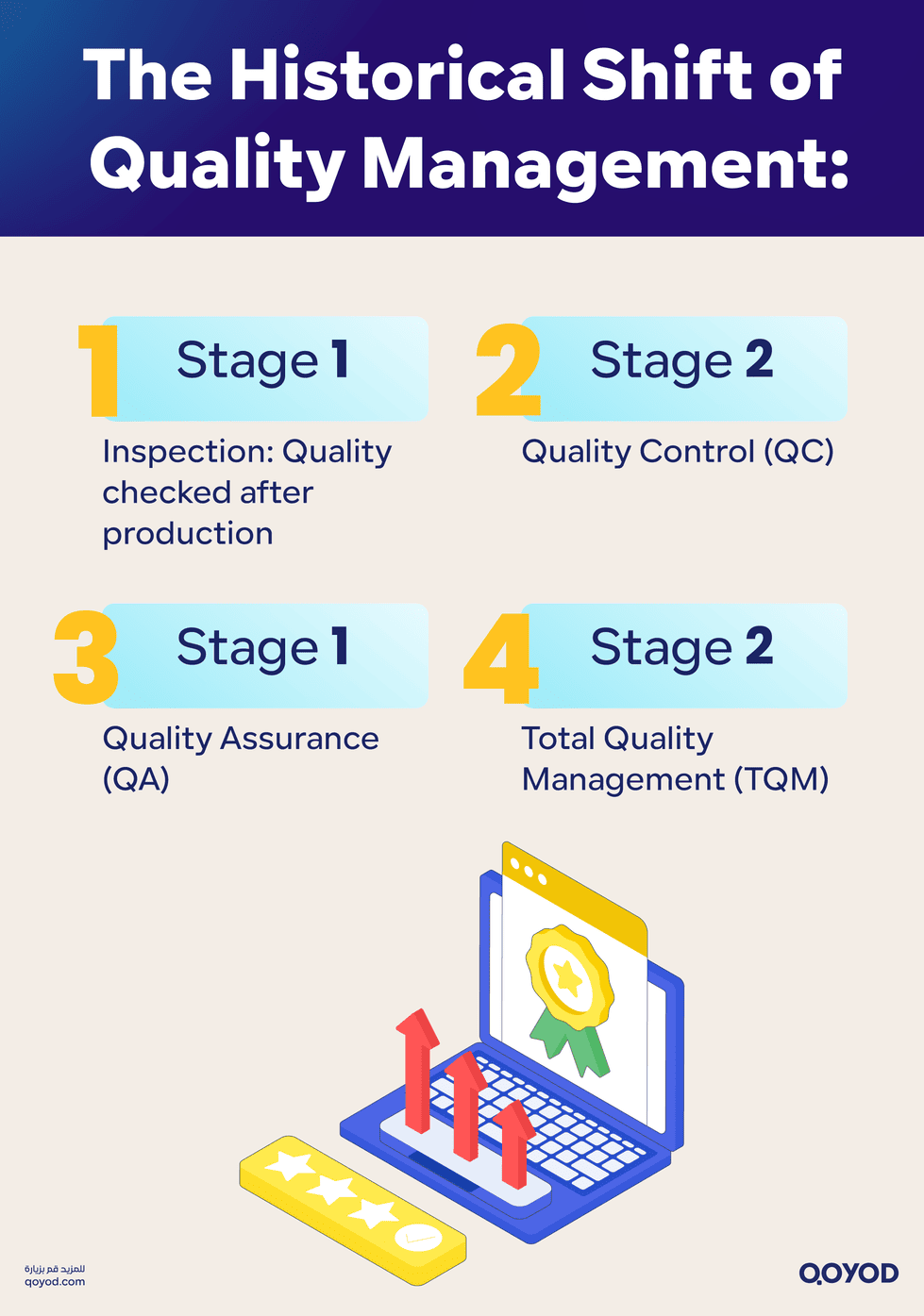

The Historical Shift: From Inspection to Integration

The evolution of quality management is a journey that mirrors industrial advancement. Initially, quality was simple inspection on the assembly line. Following World War II, the principles that would eventually form TQM began to crystallize, pioneered by figures like W. Edwards Deming and Joseph Juran.

This historical shift moved through several critical stages:

- Stage 1: Inspection (Post-Production): Focus was on checking finished goods and removing defects.

- Stage 2: Quality Control (QC): Introduced statistical sampling and process monitoring, moving quality intervention earlier.

- Stage 3: Quality Assurance (QA): Focused on designing the system to prevent failures in the first place, using documentation and standardization.

- Stage 4: Total Quality Management (TQM): Integrated quality assurance and control into a strategic, organization-wide philosophy. This marked the shift from viewing quality as a departmental task to seeing it as a core business strategy and a driver for sustainable growth. This integration ensures quality considerations are baked into strategic planning, design, execution, and customer feedback loops.

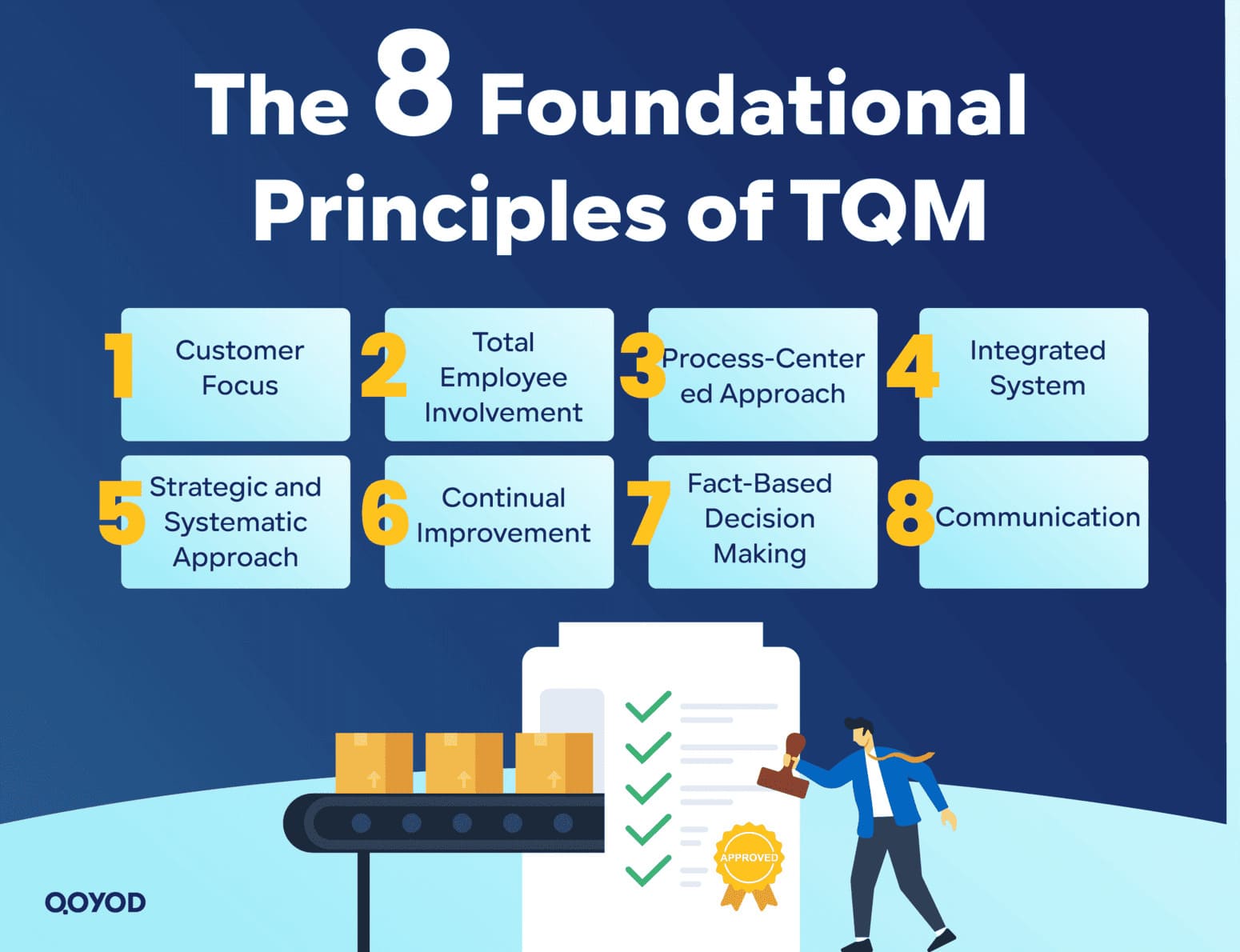

The 8 Foundational Principles of TQM

TQM is built upon a set of core principles that guide the organization’s behavior and decisions. These principles transform quality from a departmental goal into a pervasive organizational culture. By adhering to these eight pillars, businesses can create a robust framework for operational excellence and consistency.

-

Customer Focus: The Ultimate Arbiter of Quality

In TQM, the customer is the ultimate judge of quality. This principle mandates that the organization understands, meets, and strives to exceed customer needs and expectations. It requires actively listening to customer feedback, both positive and negative, and using that data to drive product design, service delivery, and process improvements. Satisfied customers are not just end-users; they are partners in the quality process, fueling market reputation and growth.

-

Total Employee Involvement: Empowering the Workforce

Quality cannot be achieved without the full commitment of every person within the organization. This principle emphasizes empowering employees at all levels to identify problems, suggest solutions, and take ownership of their processes. When employees are well-trained, motivated, and provided with the right tools, they become the most effective agents of continuous improvement.

-

Process-Centered Approach: Managing Activities as Processes

A fundamental TQM realization is that most defects are caused by poor processes, not poor individual performance. This principle requires managing activities as interconnected processes. By focusing on process measurement, monitoring, and control, organizations can identify bottlenecks, eliminate waste, and achieve predictable, high-quality outcomes consistently.

-

Integrated System: Unifying the Organization

For TQM to be effective, all systems and departments must be integrated horizontally. An organization’s structure, policies, and culture must be understood as an interconnected system working toward a single goal: quality. This principle ensures seamless operations and prevents the development of “silos” where departments operate independently, often conflicting with overall quality goals.

-

Strategic and Systematic Approach: Quality as a Strategy

Quality is not a standalone operational goal; it must be a core component of the organization’s strategic plan. The systematic approach involves defining the vision, mission, policies, and strategic goals that promote quality. Integrating quality management into the overall business strategy ensures that resource allocation and decision-making are consistently aligned with the quality objective.

-

Continual Improvement: The Kaizen Philosophy

Continual improvement (often known as Kaizen) is perhaps the most famous principle of TQM. It is the commitment to constantly looking for ways to improve efficiency, effectiveness, products, and services. This principle dictates that improvement is a never-ending journey, often relying on small, incremental changes rather than relying solely on large, revolutionary overhauls. A commonly used model for this is the Plan-Do-Check-Act (PDCA) cycle.

-

Fact-Based Decision Making: Data Over Intuition

Effective TQM relies on data, not guesswork. Decisions regarding quality improvements should be based on the analysis of accurate, reliable, and up-to-date data. This requires organizations to establish robust systems for collecting and analyzing performance metrics, customer satisfaction scores, and process measurements. Tools like statistical process control (SPC) enable informed decision-making.

-

Communication: Openness and Clarity

Effective communication is the lubricant that keeps the TQM machine running smoothly. This principle ensures that quality policies, improvement plans, and performance data are clearly communicated across all levels of the organization. Open and honest communication between management, employees, and customers is vital for ensuring alignment and commitment to the quality philosophy.

The Role of TQM in Modern Business Operations

In today’s hyper-connected and rapidly changing global market, TQM is more than just a philosophy; it is a vital operational engine that drives competitive advantage. By focusing the entire organization on process optimization and customer value, TQM delivers tangible results across the board.

Improving Efficiency and Reducing Waste (Lean Management Synergy)

A primary operational benefit of TQM is the significant improvement in efficiency and the reduction of organizational waste. The process-centered approach inherent in TQM naturally aligns with Lean Management principles. By continuously analyzing workflows and identifying non-value-added steps, TQM helps companies:

- Minimize scrap and rework costs.

- Shorten production and service delivery cycles (cycle time reduction).

- Optimize resource utilization (time, materials, and human effort).

This synergistic focus ensures that every resource is directed towards activities that enhance customer value, leading directly to lower operating costs and higher profit margins.

Enhancing Customer Loyalty and Retention

The commitment to Customer Focus, a cornerstone of TQM, translates directly into superior customer experiences. When quality is built into every touchpoint, from the initial product inquiry to after-sales support, customers develop trust and satisfaction. High satisfaction levels are crucial because retaining an existing customer is significantly more cost-effective than acquiring a new one. TQM systematically enhances:

- Product reliability and durability.

- Service responsiveness and professionalism.

- Overall brand reputation, leading to repeat business and positive word-of-mouth referrals.

Cultivating a Culture of Accountability and Quality

TQM fundamentally changes the organizational culture from reactive to proactive. By involving all employees and making quality everyone’s responsibility, it fosters a culture where accountability thrives. Employees are empowered to stop production if quality is compromised (a concept known as Jidoka), ensuring issues are addressed immediately at the source. This shared responsibility cultivates an environment of continuous learning, psychological safety, and excellence, reducing resistance to change and driving long-term organizational health.

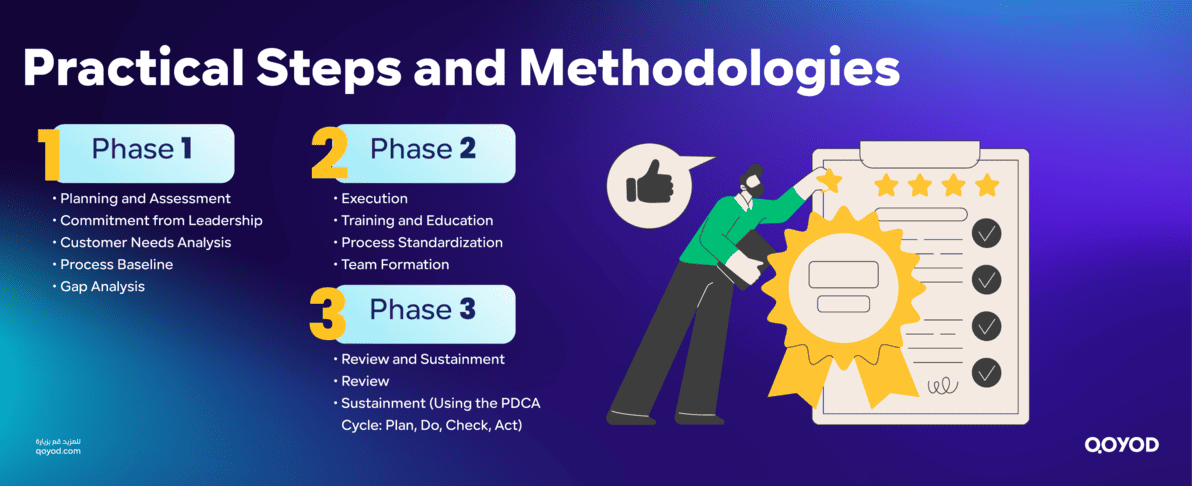

Implementing TQM: Practical Steps and Methodologies

Adopting TQM is a transformation, not a quick fix. Successful implementation requires a structured, multi-phase methodology that systematically integrates the principles into daily operations.

Phase 1: Planning and Assessment (Identifying Gaps)

The initial phase is critical for laying the groundwork and securing leadership buy-in. It involves a thorough assessment of the current state of the organization.

- Commitment from Leadership: TQM must be championed by top management who provide the vision, resources, and commitment to change.

- Customer Needs Analysis: Defining external and internal customer requirements.

- Process Baseline: Documenting current processes and measuring key performance indicators (KPIs) to establish a baseline.

- Gap Analysis: Identifying the disparity between current performance and the desired quality standards.

Learn More About :strategic planning, its relevance, aims, and stages.

Phase 2: Execution (Training and Process Standardization)

With a clear plan, the execution phase focuses on enacting the required changes and equipping the workforce.

- Training and Education: Comprehensive training for all employees on TQM principles, problem-solving techniques, and specific quality tools.

- Process Standardization: Defining optimal processes and creating standard operating procedures (SOPs) to ensure consistency.

- Team Formation: Creating cross-functional teams responsible for managing specific improvement projects.

Phase 3: Review and Sustainment (Using the PDCA Cycle)

Sustainability is the ultimate measure of TQM success. This phase ensures that improvements are maintained and the organization remains dedicated to continuous evolution.

- Review: Regularly auditing processes and measuring results against the established KPIs.

- Sustainment (Using the PDCA Cycle): The Plan-Do-Check-Act (PDCA) cycle is central here. Teams use it to systematically:

- Plan: Identify a problem and plan a solution.

- Do: Implement the solution on a small scale.

- Check: Measure the results and compare them against the plan.

- Act: Standardize the successful change or begin the cycle again if results are unsatisfactory.

Key TQM Tools: The 7 Basic Quality Tools

Implementation often relies on a common set of analytical and data visualization tools that empower employees to understand, measure, and solve quality issues. These include:

- Check Sheets: Simple forms for collecting data in real-time.

- Pareto Chart: Visualizing defect frequency to prioritize the “vital few” causes (e.g., the 80/20 rule).

- Cause-and-Effect Diagram (Fishbone Diagram): Identifying potential causes of a problem (Effect) by categorizing inputs (Causes: Man, Machine, Material, Method, Measurement, Environment).

- Histogram: Showing the frequency distribution of continuous data.

- Scatter Diagram: Displaying the relationship between two variables.

- Control Charts: Monitoring processes over time to detect variation.

- Flowcharts: Mapping the steps of a process for clear understanding.

TQM vs. Other Quality Frameworks (ISO 9001, Six Sigma)

While Total Quality Management (TQM) establishes the foundational philosophy and cultural mindset for excellence, it often works in conjunction with other formal quality frameworks. Understanding the relationships between TQM, ISO 9001, and Six Sigma is crucial to building a holistic quality strategy.

| Framework | Primary Focus | Scope | Relationship to TQM |

| TQM | Philosophy and Culture (Customer Focus, Employee Involvement) | Organization-Wide Mindset | The overarching strategy and cultural foundation. |

| ISO 9001 | Standardization and Documentation (Requirements for a Quality Management System – QMS) | Certification and Compliance | Provides the documented system structure to support TQM principles. |

| Six Sigma | Process Improvement and Variation Reduction (Statistical methodologies) | Project-Specific, Data-Driven Problem Solving | Provides the specific analytical tools for the ‘Fact-Based Decision Making’ principle of TQM. |

In essence, ISO 9001 tells you what to do (document your quality system), and Six Sigma tells you how to solve specific high-impact process problems using data. TQM provides the organizational why (customer value) and the cultural ethos (continuous improvement) that binds these tools and standards together into a unified strategic approach.

Future of Quality Management: TQM in the Digital Age

The core principles of TQM customer focus, process control, and data-driven decisions are more relevant than ever in the digital era. Modern technology does not replace TQM; it amplifies its power, transforming traditional quality management into a proactive, predictive discipline.

In the past, gathering performance data was labor-intensive. Today, systems generate massive datasets instantaneously. TQM principles are now enhanced by:

- Predictive Quality: Artificial Intelligence (AI) and Machine Learning (ML) can analyze real-time operational data to predict potential equipment failures or quality deviations before they occur, shifting quality from prevention to prediction.

- IoT for Process Monitoring: The Internet of Things (IoT) sensors embedded in production equipment allow for constant, granular process monitoring, providing the definitive, fact-based data required for continuous improvement.

- Enhanced Customer Insight: Advanced analytics allow businesses to capture and interpret diverse forms of customer feedback (social media, support tickets, usage patterns), giving a much clearer, real-time picture of customer satisfaction the ultimate TQM metric.

By integrating these digital capabilities, TQM moves from simply managing quality to orchestrating intelligent operational excellence at scale.

Read More:

Year Over Year (YOY) Analysis: A Complete Guide to Business Growth & Performance Metrics

At Sum Up :

Total Quality Management (TQM) is a comprehensive journey, not a destination. It is a fundamental strategic choice that requires long-term commitment from the highest levels of management. The investment in TQM ultimately yields significant returns: reduced operating costs through waste elimination, improved market standing through customer loyalty, and a resilient, adaptive organizational culture. It provides the blueprint for business excellence that ensures an organization can not only survive but thrive and achieve sustainable growth regardless of global economic challenges.

For businesses looking to operationalize these principles,to move beyond philosophy into measurable actionthe right financial and operational tools are indispensable. Effective financial management software is essential for tracking the KPIs, measuring the financial impact of quality improvements, and providing the accurate, real-time data needed for fact-based decision making across the entire integrated system.

Frequently Asked Questions (FAQs) About TQM

What is the fundamental difference between TQM and Quality Control (QC)?

TQM is a comprehensive, strategic philosophy focused on preventing defects and ensuring continuous improvement across every department in the organization. Quality Control (QC) is primarily an operational step focused on detecting defects in the finished product or service.

What are the three core principles of TQM?

The three core pillars of Total Quality Management are: Customer Focus (quality is defined by the customer), Process Centricity (focusing on improving systems rather than fixing people), and Total Employee Involvement (quality is everyone's responsibility).

How does TQM relate to Lean Management?

TQM and Lean Management are highly synergistic. TQM provides the cultural framework (continuous improvement and process focus), while Lean provides the specific tools and methods necessary for TQM to achieve one of its primary goals: the elimination of waste and non-value-added activities.

Is TQM applicable to service industries, or only manufacturing?

TQM is highly applicable to all industries, including services, healthcare, and finance. The focus shifts from product quality to the quality of service delivery, customer experience, and process efficiency, ensuring the TQM principles remain universally relevant.

What is the PDCA cycle, and why is it essential to TQM?

The PDCA cycle (Plan-Do-Check-Act) is the foundational methodology for continual improvement (Kaizen). It ensures that any change or improvement is implemented, measured, and standardized systematically, preventing organizations from stagnating or reverting to old habits.

How does TQM use data?

TQM relies on Fact-Based Decision Making. It requires organizations to collect and analyze accurate performance data, quality metrics, and customer feedback (often using the 7 Basic Quality Tools) to identify root causes and measure the success of improvement initiatives, moving decisions beyond intuition.

What is the role of top management in TQM implementation?

Top management's role is critical. They must provide the vision, commitment, and resources to champion the TQM philosophy. Their involvement sets the tone for the entire organization, ensuring that TQM is treated as a strategic priority, not just an optional project.

Is TQM a replacement for ISO 9001 certification?

No. ISO 9001 is a standard that provides a documented set of requirements for establishing a Quality Management System (QMS). TQM is the overarching philosophy and cultural approach. ISO 9001 provides the structural framework to help an organization implement and document TQM principles effectively.

How can modern technology (AI/IoT) enhance TQM?

Modern technology transforms TQM from reactive to predictive. AI and data analytics predict quality issues before they occur, IoT sensors provide real-time process data for immediate control, and advanced analytics give deeper insight into customer feedback—all supporting fact-based decisions and continuous improvement.

How does financial management software support TQM principles?

Financial software is the engine for TQM's Fact-Based Decision Making and Integrated System principles. It tracks KPIs, calculates the financial return on investment (ROI) of quality projects, and provides the accurate, centralized data needed to measure cost reduction and sustained profitability.

What is the fundamental difference between TQM and Quality Control (QC)?

TQM is a comprehensive, strategic philosophy focused on preventing defects and ensuring continuous improvement across every department in the organization. Quality Control (QC) is primarily an operational step focused on detecting defects in the finished product or service.

What are the three core principles of TQM?

The three core pillars of Total Quality Management are: Customer Focus (quality is defined by the customer), Process Centricity (focusing on improving systems rather than fixing people), and Total Employee Involvement (quality is everyone's responsibility).

How does TQM relate to Lean Management?

TQM and Lean Management are highly synergistic. TQM provides the cultural framework (continuous improvement and process focus), while Lean provides the specific tools and methods necessary for TQM to achieve one of its primary goals: the elimination of waste and non-value-added activities.

Is TQM applicable to service industries, or only manufacturing?

TQM is highly applicable to all industries, including services, healthcare, and finance. The focus shifts from product quality to the quality of service delivery, customer experience, and process efficiency, ensuring the TQM principles remain universally relevant.

What is the PDCA cycle, and why is it essential to TQM?

The PDCA cycle (Plan-Do-Check-Act) is the foundational methodology for continual improvement (Kaizen). It ensures that any change or improvement is implemented, measured, and standardized systematically, preventing organizations from stagnating or reverting to old habits.

How does TQM use data?

TQM relies on Fact-Based Decision Making. It requires organizations to collect and analyze accurate performance data, quality metrics, and customer feedback (often using the 7 Basic Quality Tools) to identify root causes and measure the success of improvement initiatives, moving decisions beyond intuition.

What is the role of top management in TQM implementation?

Top management's role is critical. They must provide the vision, commitment, and resources to champion the TQM philosophy. Their involvement sets the tone for the entire organization, ensuring that TQM is treated as a strategic priority, not just an optional project.

Is TQM a replacement for ISO 9001 certification?

No. ISO 9001 is a standard that provides a documented set of requirements for establishing a Quality Management System (QMS). TQM is the overarching philosophy and cultural approach. ISO 9001 provides the structural framework to help an organization implement and document TQM principles effectively.

How can modern technology (AI/IoT) enhance TQM?

Modern technology transforms TQM from reactive to predictive. AI and data analytics predict quality issues before they occur, IoT sensors provide real-time process data for immediate control, and advanced analytics give deeper insight into customer feedback—all supporting fact-based decisions and continuous improvement.

How does financial management software support TQM principles?

Financial software is the engine for TQM's Fact-Based Decision Making and Integrated System principles. It tracks KPIs, calculates the financial return on investment (ROI) of quality projects, and provides the accurate, centralized data needed to measure cost reduction and sustained profitability.