| Expert

Streamline your entire Procurement Cycle from request to payment with expert guidance. Learn the essential stages, documentation, and challenges to optimize your spending and inventory. Leverage Qoyod Accounting Software to automate financial settlements and gain complete control over your small and medium-sized business (SMB) purchasing process. |

The Procurement Cycle is a sequence of structured and coordinated operations and steps that encompass all necessary activities to acquire the products or services a business needs effectively and affordably. This cycle aims to ensure the timely supply of materials, meeting the required quality standards and achieving the best prices, all while managing vendor relationships and maximizing operational efficiency.

The Procurement Cycle: Definition, Steps, and Global Importance

The Procurement Cycle is a critical function for every small to medium-sized business (SMB) globally. Effectively managing this cycle is essential for cost control, efficiency, and sustained profitability.

Defining the Procurement Cycle in Detail

The Procurement Cycle is defined as the complete path from the initial identification of a need for a product or service, through information gathering and evaluation, supplier selection, finalization of the purchase, receipt of goods, payment processing, and the organized documentation of every stage. This ensures traceability, financial compliance, and administrative adherence to internal policies.

Essential Steps in the Procurement Cycle

- Need Identification: Determining the necessary tools, materials, or services for purchase, aligned with the business plan and strategic objectives.

- Request for Quotations (RFQ): Contacting potential suppliers to obtain price offers and comparing available options.

- Supplier Selection: Evaluating proposals based on price, quality, delivery times, and selecting the most suitable vendor.

- Issuing a Purchase Order (PO): Formalizing the agreement with the vendor via an official document that acts as a legally binding purchasing contract.

- Receiving and Inspection: Taking delivery of the materials and confirming they meet the specified quality and quantity requirements.

- Review and Settlement: Matching the vendor invoices with the purchase orders and goods receipt notes (Three-Way Matching), followed by payment to the supplier.

- Documentation: Recording all operations and documents related to the purchasing process for tracking and auditing purposes.

Importance of the Procurement Cycle for SMBs

A well-managed Procurement Cycle enables businesses to reduce costs, improve efficiency, enhance vendor relationships, and ensure a continuous and uninterrupted supply of essential materials. This is fundamental for achieving sustainable success and profitability in today’s competitive global market.

Learn More: What is purchasing management, and why is it important?

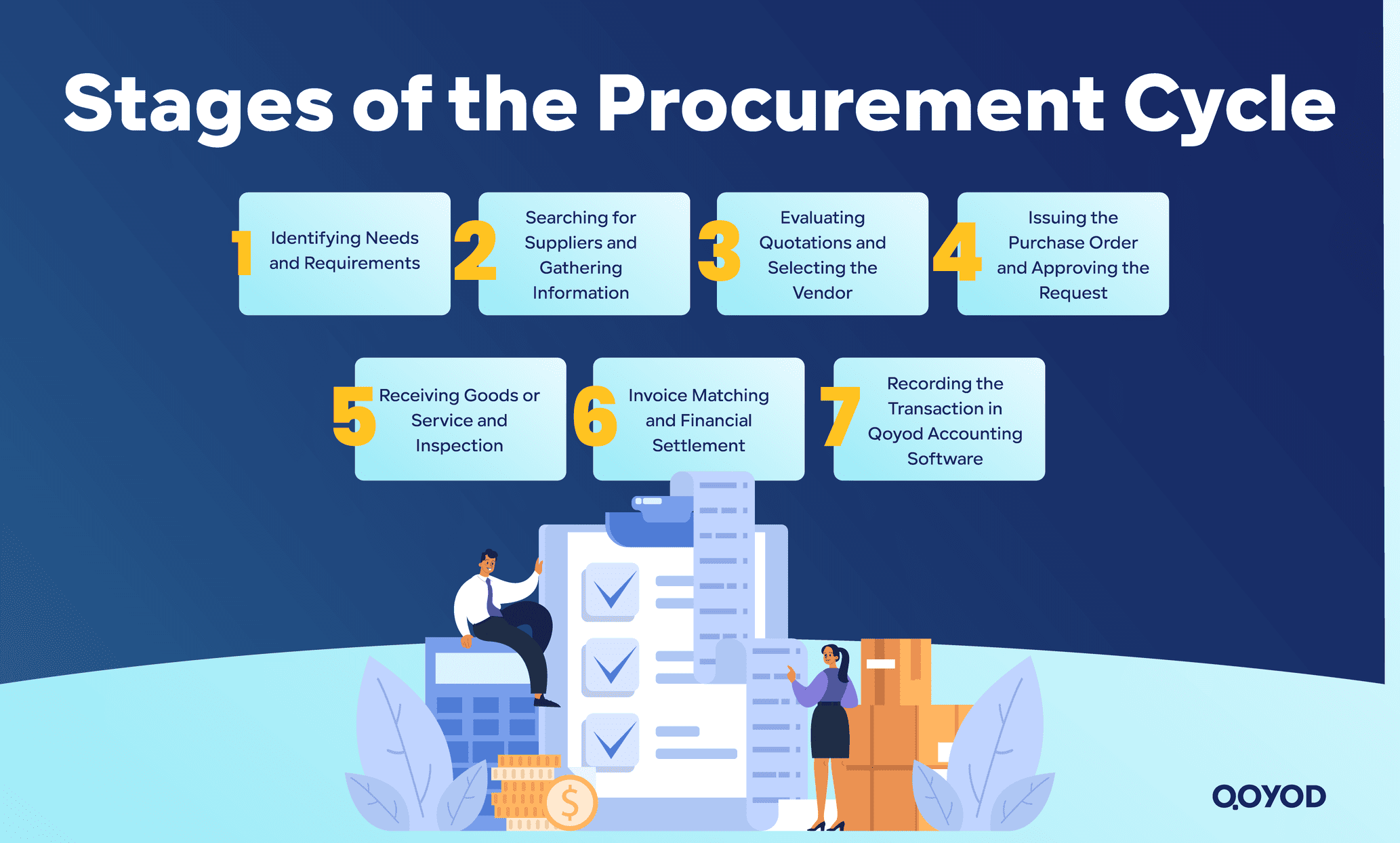

Stages of the Procurement Cycle

The stages of the Procurement Cycle are a set of fundamental steps ensuring the purchasing process is completed in an organized and efficient manner.

1. Identifying Needs and Requirements

The Procurement Cycle begins with a clear and detailed definition of the organization’s need for materials or services. This includes specifying the type, quantity, quality, and specifications of what must be purchased, based on the business plan and analysis of actual demand to ensure operational requirements are met without surplus inventory or shortages.

2. Searching for Suppliers and Gathering Information

In this stage, potential suppliers are sourced through various channels. Data is collected on product quality, pricing, delivery schedules, vendor reputation, and contract terms. The goal is to create a shortlist of vendors capable of efficiently meeting the organization’s requirements.

3. Evaluating Quotations and Selecting the Vendor

After receiving price quotes and technical proposals, the procurement team analyzes and compares them based on cost, quality, adherence to deadlines, and payment terms, to choose the optimal offer that provides the best value for money.

4. Issuing the Purchase Order and Approving the Request

A formal Purchase Order (PO) is issued, containing all relevant details about the requested products or services in terms of quantities, prices, and delivery dates. The PO undergoes an internal approval process to ensure the request aligns with the budget and approved policies.

5. Receiving Goods or Service and Inspection

Upon arrival of the goods or delivery of the service, a thorough inspection is conducted to ensure conformity with the agreed specifications in terms of quality and quantity. A Goods Receipt Note (GRN) is issued to confirm the acceptance of the supply.

6. Invoice Matching and Financial Settlement

The vendor’s invoice is compared with the Purchase Order and the Goods Receipt Note in a process called “Three-Way Matching”. This ensures that payment is made only for what was actually received and that there are no errors or discrepancies.

7. Recording the Transaction in Qoyod Accounting Software

At this crucial step, all accounting documents,from the purchase request, PO, receipt, invoice, to the payment—are documented within the Qoyod Accounting Software system. This automatically updates financial accounts, such as Accounts Payable and Inventory, facilitating streamlined financial auditing and performance analysis.

These stages ensure that the procurement objectives,saving time, better cost control, and ensuring the quality and availability of materials,are met, with accurate documentation and monitoring via modern accounting systems.

Watch Now : How to manage sales and purchase invoices

The Procurement Document Cycle (Paper Trail)

The Procurement Document Cycle refers to the organized system for documenting and recording all paperwork and files related to the purchasing process within the organization. This is essential for procedural control, ensuring transparency, and strengthening financial and administrative oversight.

Key Documents in the Procurement Document Cycle

- Purchase Requisition (PR):

This is the initiating document. The department or unit needing the items specifies the necessary goods, quantities, and specifications. It requires internal approvals to ensure the purchase is planned and authorized.

- Requests for Quotation (RFQ):

Sent to potential vendors to obtain detailed price quotes, allowing for comparison of prices, quality, and terms to select the most favorable offer.

- Purchase Order (PO):

The official document issued by the procurement department to the selected vendor. It includes all details: items, quantities, prices, delivery dates, and payment terms, forming a binding contract.

- Contracts:

Used for larger operations or those requiring special terms. All legal and technical clauses are documented to guarantee the rights and obligations of both parties.

- Goods Receipt Note (GRN):

Serves as proof of receipt of goods or services. It is issued by the receiving department after inspection confirms the received materials match the required specifications and quantities.

- Purchase Invoice:

Submitted by the vendor as a request for payment. The invoice details must match the Purchase Order and the Goods Receipt Note to prevent errors and financial fraud.

- Payment Documents:

Includes payment notifications, payment vouchers, or checks, documenting the settlement of dues to vendors.

The Importance of Organization and Control in Documentation

| Aspect | Explanation |

| Compliance | Documenting every step of the Procurement Cycle ensures adherence to internal procedures and approved financial policies, preventing disputes and misappropriation. |

| Transparency | Standardized files allow easy review and tracking of operations by different departments and auditors. |

| Financial Control | Documents facilitate verification of purchases and their alignment with approvals and budgets. |

| Decision Support | Reports based on documentation provide accurate information for improving purchasing strategies and reducing costs. |

| Audit and Legal Compliance | Aids in providing clear documentation during internal or external audits and complying with regulatory requirements. |

By utilizing digital systems like Qoyod Accounting Software, this document cycle can be automated to reduce errors, expedite processes, and increase efficiency in managing procurement for modern businesses.

Challenges in the Procurement Cycle

The Procurement Cycle faces several challenges that affect the efficiency and effectiveness of purchasing operations within an organization.

1. Price Volatility

Raw material and commodity prices change frequently due to inflation, currency exchange rate fluctuations, and supply chain disruptions. This makes it difficult to predict procurement costs and negatively impacts planned budgets.

2. Limited Supplier Base

In some industries, the number of suppliers may be limited or dominated by a few players, which reduces negotiation opportunities for the best prices and exposes the organization to the risk of reliance on a single source.

3. Weak Systems and Technology

Reliance on manual or non-integrated systems leads to data errors, slow operations, and difficulty in accurately tracking purchasing transactions, impeding sound decision-making.

4. Delayed Deliveries

Supplier delays in delivering materials disrupt workflow and cause production halts, affecting adherence to deadlines and increasing operating costs.

5. Poor Information Quality

A lack of accurate information about products and suppliers makes it difficult to correctly evaluate offers, exposing the company to the risk of purchasing products of substandard quality.

6. Budgetary Constraints and Administrative Friction

The procurement department may face financial constraints preventing them from purchasing the required quantities or quality, in addition to administrative friction that can delay approvals or limit flexibility in decision-making.

7. Legal and Regulatory Compliance

Unfamiliarity with tax, customs, and environmental regulations can lead to legal risks and financial penalties, affecting the company’s reputation and regulatory adherence.

Strategies to Overcome Challenges and Enhance Efficiency

- Use Integrated Technology Systems: Implement ERP or systems like Qoyod that facilitate accurate transaction documentation and data analysis, improving decision speed and operational efficiency.

- Diversify Sourcing: Search for new vendors and diversify supply sources to minimize dependency on a single supplier.

- Develop Procurement Team Skills: Provide continuous training to enhance negotiation and risk management capabilities.

- Regular Market Monitoring: Track changes in prices, supply, and demand to respond quickly.

- Adopt Flexible Budget Strategies: Allow for adaptation to cost changes without disrupting operations.

- Strengthen Regulatory Oversight: Through continuous auditing to ensure the application of laws and policies.

These strategies help overcome common challenges and improve the performance of the Procurement Cycle to achieve the best operational and financial results for the organization.

The Relationship Between Procurement and Inventory

The relationship between procurement management and inventory management is crucial and symbiotic for any organization aiming for operational efficiency and waste reduction. Procurement management is responsible for acquiring the necessary materials and goods in appropriate quantities, quality, and price, while inventory management focuses on organizing the storage of these materials and ensuring continuous availability without excess or shortage.

Procurement affects inventory through continuous coordination with the warehouse management to know available quantities and consumption rates. This helps accurately determine the quantities to be purchased, thereby avoiding material shortages that disrupt production and reducing excess inventory that leads to resource waste and increased storage costs. Procurement also contributes to improving inventory quality by selecting reliable vendors who provide products that meet specifications.

Effective collaboration between the two departments also ensures optimal utilization of storage space, organization of items based on turnover rates, and simplification of periodic inventory counting. In essence, procurement plans material needs based on inventory data, and warehouse management provides accurate data on inventory levels, item status, and inflow/outflow movements.

When this relationship is applied effectively, several benefits are realized: enhancing business continuity, lowering operational costs, reducing inventory losses due to damage or improper storage, and improving the flow of information for informed purchasing decisions. Furthermore, utilizing advanced digital systems like Qoyod Accounting Software helps integrate procurement and inventory data, providing a comprehensive, real-time view of resource status, thereby supporting the organization’s financial and organizational performance.

Summary of the Procurement and Inventory Relationship

| Aspect | Elaboration |

| Coordination & Planning | Procurement works with inventory to set purchasing schedules and quantities that meet business needs and consider storage capacities. |

| Quantity Determination | Procurement determines purchase quantities in collaboration with inventory based on stock levels (Minimum Stock, Reorder Point, Maximum Stock). |

| Ensuring Business Continuity | Timely material provision prevents production interruptions due to inventory shortages. |

| Cost and Waste Reduction | Avoiding overstocking reduces storage costs and waste from material damage. |

| Improving Inventory Quality | Selecting reliable vendors ensures high-quality materials, verified through warehouse inspection. |

| Data Exchange | Collaboration supports accurate information exchange on inventory movement, consumption, and material availability for better purchasing planning. |

| Enhancing Operational Efficiency | Coordination leads to item organization, easy inventory counts, and smooth material withdrawal when needed. |

| Digital Integration | Utilizing integrated accounting and management software like Qoyod enhances the integration of procurement and inventory data and strengthens financial and operational control. |

This table summarizes the key aspects of collaboration and integration between procurement and inventory departments to achieve an effective balance between material availability, operational efficiency, cost reduction, and waste minimization.

FAQ on Procurement Management and the Procurement Cycle

What is Procurement Management?

Procurement management is the organized process of acquiring the necessary materials, equipment, and services for an organization's daily and production operations, aiming to ensure their availability in a timely manner, with the best quality, and at a suitable price.

Why is the Procurement Cycle Important?

The Procurement Cycle ensures the continuity of workflow, cost control, improvement of material quality, and enhancement of vendor relationships, positively reflecting on the organization's performance and profitability.

What are the Key Stages of the Procurement Cycle?

They include identifying needs, searching for vendors, evaluating offers, issuing Purchase Orders, receiving and inspecting goods, invoice matching, and recording transactions in the accounting system.

What Documents are Used in the Procurement Document Cycle?

They include the Purchase Requisition, Requests for Quotation, Purchase Order, Contracts, Goods Receipt Notes, Invoices, and Payment Documents, which are essential for organization and control.

How Does Procurement Management Deal with Price Volatility?

It uses forecasting and market analysis, diversifies sourcing, and enters into vendor contracts to control costs and limit the risks of sudden price changes.

What is the Relationship Between Procurement and Inventory Management?

They collaborate to adjust inventory levels based on consumption and demand, preventing material shortages or surpluses, saving storage costs, and reducing waste.

How Does Procurement Management Help Reduce Waste?

By purchasing the appropriate quantities at the precise time and choosing high quality from reliable vendors, preventing goods damage or storage surplus.

What is the Importance of Documenting the Procurement Cycle?

Documentation provides transparency, ensures legal compliance, assists in auditing processes, and facilitates decision-making based on accurate and reliable data.

How Do Digital Systems Improve Procurement Management?

Accounting and procurement software like Qoyod provides automation of accounting processes, accurate reports, and speed in issuing orders and follow-up, which enhances efficiency and reduces errors.

What are the Responsibilities of a Procurement Manager?

Planning, negotiating with vendors, issuing Purchase Orders, monitoring quality and delivery, and coordinating with inventory and accounting departments to achieve the best performance and results for the organization.

At Sum Up:

In conclusion, procurement management plays a vital and fundamental role in the success of any commercial or industrial organization. It is not merely a process of purchasing materials and services but an integrated system that requires accurate planning and organized execution aimed at providing supplies with the highest quality and lowest cost in a timely manner.

Procurement management directly influences the efficiency of operational processes by fostering coordination with other departments, such as inventory and accounting, improving cash flow, and reducing waste. Furthermore, documenting operations and using modern digital solutions like integrated procurement and inventory management systems enhances transparency and aids in data-driven decision-making.

Therefore, investing in developing the skills of procurement teams, adopting flexible strategies, and utilizing appropriate technology is key to enhancing the organization’s competitive capability and achieving its strategic objectives efficiently and effectively. Ultimately, the success of procurement management contributes directly to achieving business growth and sustainability amidst a changing competitive environment.

Try Qoyod Accounting Software now to make your business operations easier and more accurate with solutions designed for modern businesses.